What you see here is a bank of 12 AGM batteries connected to 1,500 watts of solar panels. They’re configured as a 48v pack with 3 parallel sets of 4 batteries in series. Total capacity is 9kWh.

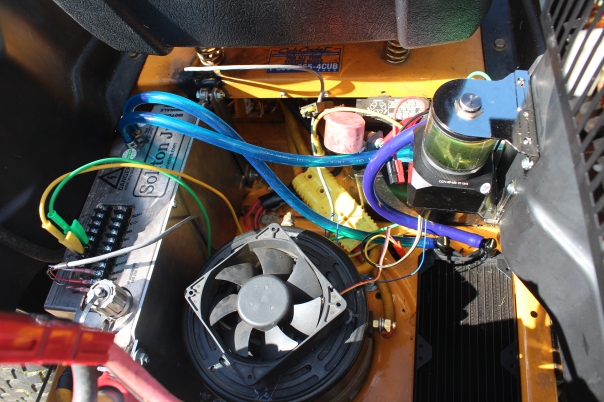

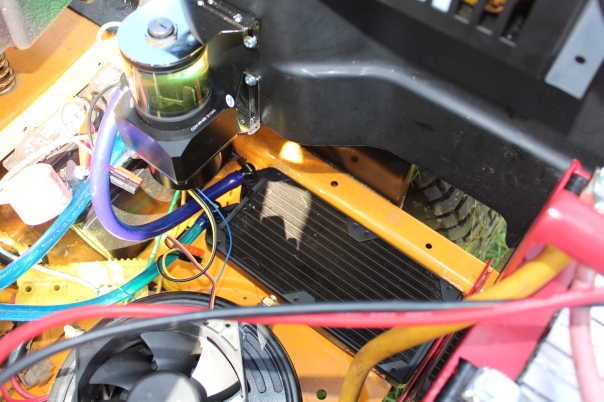

The zero turn mower has 7 Nissan Leaf cells connected in series making a 48v nominal pack. Capacity is 3kWh

The lead acid batteries store up the solar power. They can hold around 2 days of good sun. When the zero turn is depleted it can be dump charged extremely quickly. If the AGMs are full and the leaf cells empty peak currents are quite high, over 120 amps. That is about 2C into the lithiums, or a full charge in about half an hour. This is much faster than just charging the zero turn directly from the solar panels, which would take 4 hours. And it allows the use of solar power even when dark or cloudy.